The right place to look if you want to improve the digital media supply chain workflow is here. We will be looking at the challenges and trends that face the media industry today and offering some solutions. It doesn't really matter what size your company may be, but it is essential to learn about the challenges and trends within the media supply chain. These workflows will ultimately improve your bottom line, and help you achieve your content-marketing goals.

Digital media supply chain

A digital supply chain for media files and metadata is a group of processes used to manage them. Since the creation of television, movies and video, there has been a long tradition of using media asset manager (MAM). A wide variety of organizations use technology as a tool. The supply chain must maintain files throughout the production and distribution stages.

The digital media distribution chain includes several components such as content delivery networks (content delivery networks), content management systems and digital asset tracking systems. For the best results in a digital supply chain, every component must be capable of being interconnected with others and leverage artificial intelligence and automation to meet the requirements of the organization. Digital media supply chains are dynamic and must be able to adapt to changing market demands.

Challenges

Lack of standardization is often the root cause of problems in media supply chain workflow. Because consumers expect content that can be accessed from any device, standardization is key. This will help companies to manage an ever-increasing amount of content. Companies need to find ways to make their workflow more efficient and productive. There are many options to automate the workflow. These solutions have their risks.

The four major dimensions of supply chain challenges can be divided into operational, behavioural and financial. This allows managers to concentrate on issues that affect their business. For example, when a country enacts a "protectionism" policy, the supply chain will be shorter. Additionally, companies will have to spend more time filling out paperwork and crossing border checks. Final, companies may have to wait longer for goods from distant suppliers.

Solutions

A media workflow is a way to automate production, simplify storage, and meet service-level expectations. This use case describes the production process, including the data management and the lifecycle. Diversified works with its clients to identify their needs and prioritize their goals. We also create functional requirements. They can then create a system and workflow design that is successful. The company developed a unique media workflow system.

The media supply chains are digital processes that include creation, management, and delivery. As a result, the workflow for this process must be flexible and customizable. It should be able to support multiple user interfaces, as well as different application contexts. Media assets are used in a variety of ways and require different functionality. Therefore, it is crucial that the technology can support all these environments. A media supply solution should be compatible with multiple formats and devices.

Trends

The media supply chain continues to change as new technologies and approaches emerge. Content creators will place greater emphasis on consistency and performance. The recent pandemic brought new challenges to broadcasters and the media supply network. Companies will be able to optimize their workflows and create a self healing supply chain with automation technology. These technological advances are not without risks. Learn about the trends in media supply chain workflow to ensure your content is delivered on time and on budget.

The traditional supply chain is no longer sufficient for today's digital age. Consumers demand access to the latest technology as well as high-quality content. Media organizations need to transform their media supply chain in order meet consumer demand. These problems can be solved by cloud-based technologies. Media organizations without cloud solutions may not be able to meet global audience demand and will incur higher delivery costs. They may also lose viewers if they fail to meet consumer demands.

FAQ

What is Kaizen?

Kaizen refers to a Japanese term that stands for "continuous improvements." It is a philosophy which encourages employees in continuously improving their work environment.

Kaizen is based upon the belief that each person should be capable of doing his or her job well.

What is the difference between Six Sigma Six Sigma and TQM?

The main difference between these two quality management tools is that six sigma focuses on eliminating defects while total quality management (TQM) focuses on improving processes and reducing costs.

Six Sigma is a method for continuous improvement. It emphasizes the elimination of defects by using statistical methods such as control charts, p-charts, and Pareto analysis.

This method has the goal to reduce variation of product output. This is accomplished by identifying the root cause of problems and fixing them.

Total quality management involves measuring and monitoring all aspects of the organization. It also includes training employees to improve performance.

It is often used as a strategy to increase productivity.

What are the 4 main functions of management?

Management is responsible of planning, organizing, leading, and controlling people as well as resources. Management also involves setting goals and developing policies.

Management is the ability to direct, coordinate, control, motivate, supervise, train, and evaluate an organization's efforts towards achieving its goals.

Management's four main functions are:

Planning – Planning involves deciding what needs to happen.

Organizing is the act of deciding how things should go.

Directing - This refers to getting people follow instructions.

Controlling – Controlling is the process of ensuring that tasks are completed according to plan.

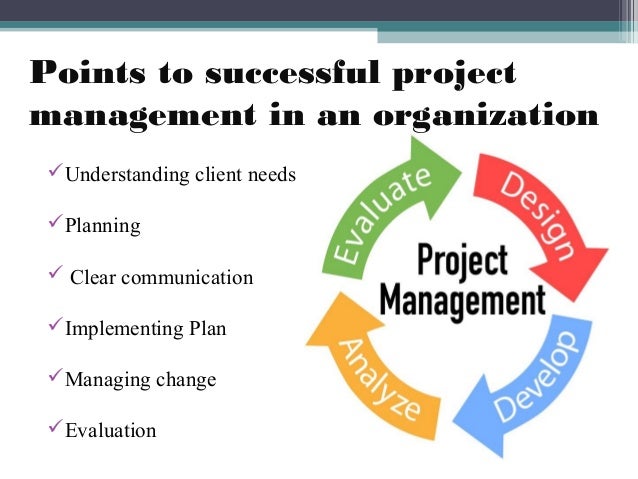

Why is it important that companies use project management methods?

Project management techniques ensure that projects run smoothly while meeting deadlines.

This is because most businesses rely heavily on project work to produce goods and services.

Companies need to manage these projects efficiently and effectively.

Companies could lose their time, reputation, and money without effective project management.

How do you define Six Sigma?

Six Sigma will most likely be familiar to people who have worked in statistics and operations research. Anyone involved in business can benefit.

Because it requires a high degree of commitment, only leaders with strong leadership skills can implement it successfully.

How do you manage employees effectively?

Effectively managing employees means making sure they are productive and happy.

It means setting clear expectations for them and keeping an eye on their performance.

Managers must set clear goals for their employees and themselves to achieve this goal.

They should communicate clearly to staff members. They also need to make sure that they discipline and reward the best performers.

They will also need to keep records about their team's activities. These include:

-

What did we accomplish?

-

What was the work involved?

-

Who did it?

-

Was it done?

-

Why did it happen?

This information can be used to monitor performance and evaluate results.

How can we make our company culture successful?

A culture of respect and value within a company is key to a productive culture.

It's founded on three principal principles:

-

Everybody has something of value to share

-

People are treated fairly

-

It is possible to have mutual respect between groups and individuals

These values are reflected in the way people behave. For example, they will treat others with courtesy and consideration.

They will listen respectfully to the opinions of others.

These people will inspire others to share thoughts and feelings.

The company culture promotes collaboration and open communication.

People can freely express their opinions without fear or reprisal.

They know mistakes will be accepted as long as they are dealt with honestly.

The company culture promotes honesty, integrity, and fairness.

Everyone is aware that truth must be told.

Everyone knows that there are rules and regulations that apply to them.

Nobody expects to be treated differently or given favors.

Statistics

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

External Links

How To

How is Lean Manufacturing done?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. They were created by Toyota Motor Corporation in Japan in the 1980s. The aim was to produce better quality products at lower costs. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It is made up of five elements: continuous improvement, continuous improvement, just in-time, continuous change, and 5S. Pull systems involve producing only what the customer wants without any extra work. Continuous improvement means continuously improving on existing processes. Just-in-time refers to when components and materials are delivered directly to the point where they are needed. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Five-S stands for sort. It is also the acronym for shine, standardize (standardize), and sustain. These five elements can be combined to achieve the best possible results.

Lean Production System

Six key concepts form the foundation of the lean production system:

-

Flow - focuses on moving information and materials as close to customers as possible.

-

Value stream mapping is the ability to divide a process into smaller tasks, and then create a flowchart that shows the entire process.

-

Five S's – Sort, Put In Order Shine, Standardize and Sustain

-

Kanban: Use visual signals such stickers, colored tape, or any other visual cues, to keep track your inventory.

-

Theory of constraints: Identify bottlenecks and use lean tools such as kanban boards to eliminate them.

-

Just-in time - Get components and materials delivered right at the point of usage;

-

Continuous improvement - incremental improvements are made to the process, not a complete overhaul.