There are many benefits of becoming a PMI member. You will have access to a wide knowledge base. You can also rest assured that you are working within a global set of standards. Volunteering is a great way to get PDUs free of charge. PMI members are able to give back to the profession and society in general. The dashboard shows the member's most recent year.

Learning and Training Opportunities

The Project Management Institute (PMI) offers a wide range of education and training opportunities for its members. Obtaining a PMI certification proves that you understand project management principles and practices. Members of the organization may also be eligible for lower certification exam fees. They may also be eligible for preparatory materials and workshops provided by PMI component organizations.

An online course is a good option if you are interested in getting a PMP certificate. These courses will help you brush up on the concepts of project management and prepare you for the exam. These courses will also allow you to earn PDUs towards your certification. PMI SeminarsWorld (tm) allows you to also attend PMI seminars. You can also earn PDUs towards your PMP certification by attending e-Symposia.

Global Conference Events

PMI members get discounts on training courses, certification exams, and other services. In order to maintain certifications, PMI members receive no-cost PDUs. In addition, members can enjoy discounts on events as well as on-demand webinars. For example, members can register to receive two premium virtual events for free and a 50% discount on three premium webinars.

These conferences are great opportunities to network with project managers. Global Conferences attract project managers from all parts of the world. Local chapters often host conferences as well. These events provide a great networking opportunity for project managers from around the world and a chance to learn about how to improve their skills.

Access to job portal

PMI members have access to a job portal that lists the latest job openings in the industry. The database is kept up-to-date and is sourced from job postings and public solicitations. Only members have access to this database. Members can register as members. Membership offers you more career opportunities as well as discounts on products or services.

PMI members also have access to a large database of career resources. It also includes a Career Headquarters and Communities of practice, where members can get advice on how to build a strong and updated resume, gain new skills, or stay current with the latest trends. A section of the job portal allows members to post their resumes. It also contains a job search tool that lets members find jobs. PMI members are also entitled to free copies of PM Network (the magazine published by PMI) and PMI Today (the magazine).

Certification fees

Cost of certification can be affected by many factors. The cost of a classroom-based course may include the fees paid to the training provider, exam costs, and time spent in training. Alternatively, you can choose to take a self-paced online course. This option is more affordable and provides many benefits such as time management. This option is flexible and available 24 hours a day. It is also much more convenient than attending class.

PMI offers discounts for its members. This means that if you are a member, the cost of a certification exam is $60 every three years. A $129 annual fee will be charged to non-members. There are many levels to PMP membership if you are interested in becoming one. A basic membership is free and a higher-level membership costs $129.

FAQ

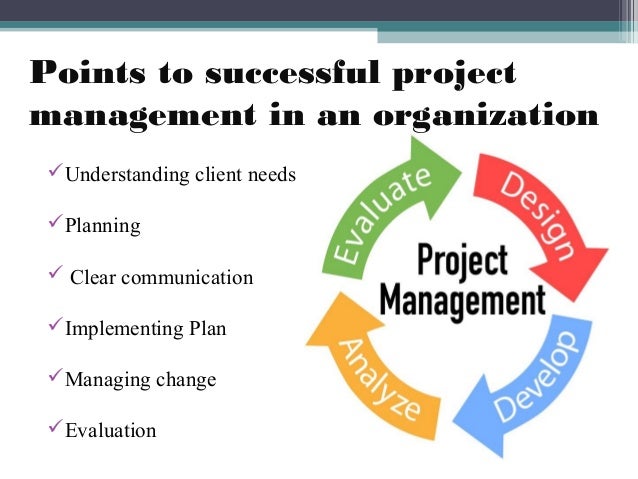

What does it mean to say "project management"

This refers to managing all activities that are involved in a project's execution.

These include planning the scope and identifying the needs, creating the budget, organizing the team, scheduling the work and monitoring progress. Finally, we close down the project.

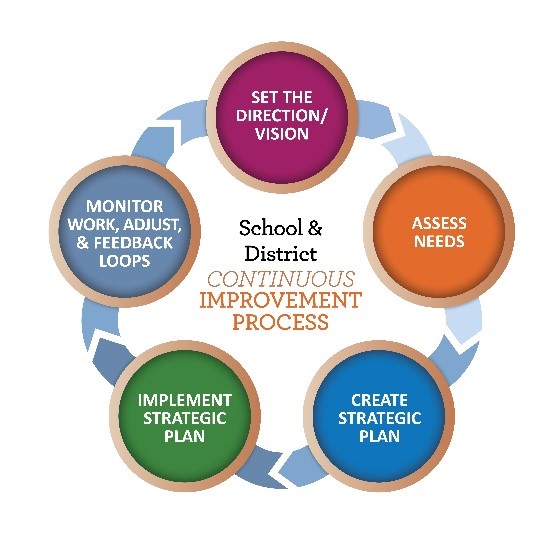

What is Six Sigma and how can it help you?

It's an approach to quality improvement that emphasizes customer service and continuous learning. This is an approach to quality improvement that uses statistical techniques to eliminate defects.

Motorola invented Six Sigma in 1986 as part its efforts to improve manufacturing.

The idea quickly spread in the industry. Many organizations today use six-sigma methods to improve product design and production, delivery and customer service.

What are the main management skills?

No matter if they are running a local business or an international one, management skills are vital. These skills include the ability manage people, finances and resources as well as other factors.

These skills are necessary for setting goals and objectives as well as planning strategies, leading groups, motivating employees and solving problems.

As you can see, there's no end to the list of managerial duties!

Statistics

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing methods are used to reduce waste through structured processes. They were developed by Toyota Motor Corporation in Japan during the 1980s. The main goal was to produce products at lower costs while maintaining quality. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It consists of five basic elements: pull systems, continuous improvement, just-in-time, kaizen (continuous change), and 5S. Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement is the continuous improvement of existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Last but not least, 5S is for sort. These five elements are combined to give you the best possible results.

Lean Production System

Six key concepts underlie the lean production system.

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S’s - Sorted, In Order. Shine. Standardize. And Sustain.

-

Kanban – visual signals like colored tape, stickers or other visual cues are used to keep track inventory.

-

Theory of constraints - identify bottlenecks in the process and eliminate them using lean tools like kanban boards;

-

Just-in Time - Send components and material directly to the point-of-use;

-

Continuous improvement - make incremental improvements to the process rather than overhauling it all at once.